Thread stripping causes delays, rework, and lost time. Whether you’re working in aluminum engine blocks or defense-grade electronics, worn threads can bring operations to a stop.

Stanley Heli-Coil® wire-threaded inserts solve this problem.

Wire-Threaded Inserts That Keep Production Moving

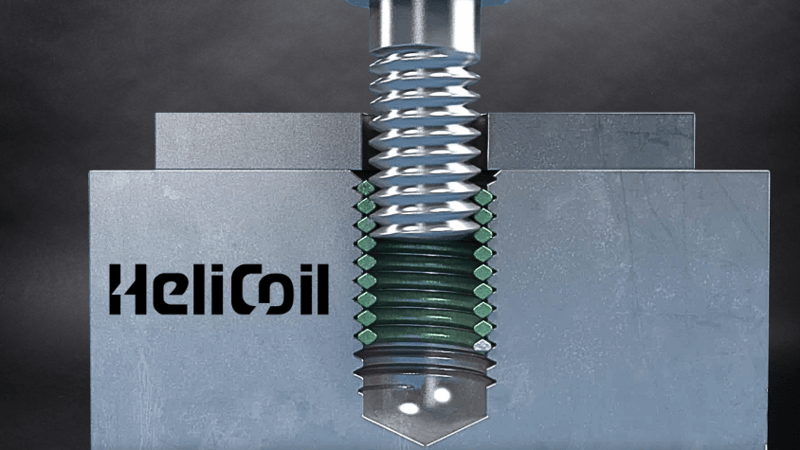

These precision-engineered inserts reinforce tapped holes with high-strength stainless-steel wire, restoring damaged threads or protecting new ones from failure under stress.

As a master stocking distributor, Hi-Tech Fasteners (HTF) offers a wide selection of Heli-Coil wire inserts, in stock and available for same-day shipping. Whether you’re building, repairing, or designing, we help you keep production running with dependable fastening solutions.

What Are Heli-Coil® Wire Inserts?

Heli-Coil® wire-threaded inserts are coiled wire inserts that create durable internal threads inside soft or damaged materials. Installed into a tapped hole, they form a precise, corrosion-resistant thread that matches the original fastener size and pitch.

Key Characteristics

- Made of stainless-steel and other wire formed into a helical coil

- Inserts into standard tapped holes

- Matches original thread form and pitch

- Locks in place with friction or optional tangs

- Supports high-torque and high-vibration environments

Heli-Coil® wire inserts offer a balance of strength, weight savings, and simplicity. They are widely used for both thread repair and thread protection in original assemblies.

Benefits at a Glance:

- Prevents thread stripping in soft metals like aluminum and magnesium

- Distributes stress over a wide area of the parent material

- Increases the load-bearing capacity of tapped threads

- Withstands repeated assembly and disassembly

- Resists vibration, corrosion, and extreme temperature cycles

- Saves time and material cost compared to oversized repairs or part replacements

In short, they create stronger, longer-lasting threads that withstand real-world conditions.

Applications Across Industries

Stanley Heli-Coil® wire-threaded inserts are trusted in industries where performance, reliability, and serviceability matter.

Automotive

- Used in aluminum components like engine blocks, heads, and housings

- Ideal for spark plugs, valve covers, and oil drain plugs

- Prevents costly rework due to stripped threads

Defense & Aerospace

- Supports secure fastening in light alloys used in aircraft and military vehicles

- Withstands high vibration and shock

- Reduces FOD (foreign object debris) risk in sensitive systems

Heavy Equipment & Industrial Machinery

- Reinforces threaded holes in large castings or structural parts

- Enables fast, reliable repairs in the field

- Performs in high-load, high-vibration environments

Heli-Coil® vs. Other Thread Repair Options

When it comes to thread reinforcement, Heli-Coil® wire-threaded inserts offer the ideal combination of strength, ease of installation, and long-term reliability. They’re lightweight, reusable, and perfect for protecting threads in aluminum and other soft metals. Their ability to resist vibration makes them a top choice in automotive, aerospace, and industrial applications.

In comparison, solid inserts, such as key-locking types, provide excellent holding strength for high-load applications. However, they are heavier, more expensive, and require more complex installation, making them better suited for permanent structural repairs.

Basic thread repair kits, like oversized taps or temporary plugs, may be affordable, but they’re not durable under stress. These are typically used for low-load or emergency fixes and often lack long-term reliability.

For most production and maintenance needs, Heli-Coil® wire inserts deliver the best balance of performance, repeatability, and cost.

Stay Stocked with Stanley Heli-Coil® Inserts Using InventoryXpert™

For manufacturers and engineering teams that rely on Stanley Heli-Coil wire-threaded inserts, maintaining the correct inventory is crucial. Whether you’re using them in ongoing production or scheduled maintenance, having the right insert at the right time keeps work moving.

HTF’s InventoryXpert™ system helps ensure you don’t run out. With barcode scanning, reorder point tracking, and support for your own part numbers and bins, InventoryXpert™ gives you visibility and control over insert usage — right at the point of storage or use.

Learn more about InventoryXpert

Stanley Inserts, Ready When You Are

Stanley Heli-Coil® wire-threaded inserts are the go-to choice for engineers who need dependable thread strength in soft metals, high-vibration environments, or thread repair situations. Their performance is proven, their installation is simple, and their availability through HTF means you don’t have to wait when quality matters most.

.png?width=800&name=InventoryXpert-Blog-Alt%20(5).png)