Dependable Thread Repair with Acme Inserts

Thread damage can halt production, delay maintenance, and lead to expensive part replacements. Whether you're in manufacturing, aerospace, or heavy equipment repair, stripped threads aren't just an annoyance—they’re a serious liability.

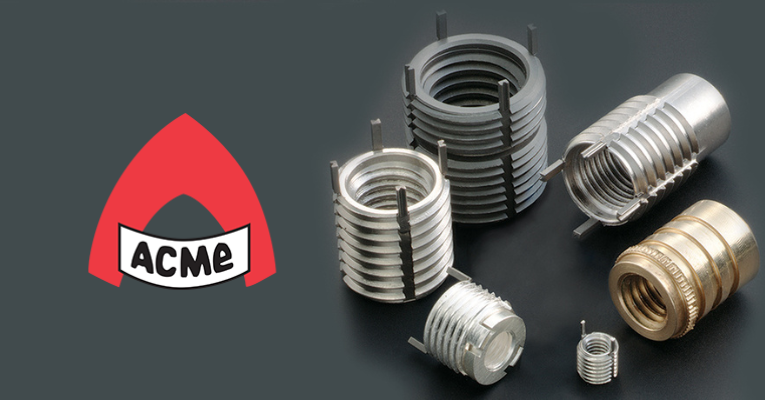

That’s why Acme Industrial's keylocking threaded inserts and thread repair bushings are trusted across industries. They restore and reinforce threads with unmatched reliability. At HTF, we supply Acme’s full line of inserts, drill bushings, and repair components—with technical support, fast shipping, and inventory control tools to match.

What Are Keylocking Inserts?

Keylocking threaded inserts, also known as Keenserts®, are metal sleeves with internal threads that reinforce or restore tapped holes in soft or damaged materials. These inserts are installed into a tapped hole and locked in place using built-in keys that are driven into predrilled slots. This locks the insert against vibration or torque, ensuring it won’t back out.

Available in a range of sizes and materials, Acme’s keylocking inserts work for:

- New builds and retrofits

- Aluminum and magnesium castings

- High-wear, high-vibration environments

At HTF, we offer a broad selection of Acme inserts, including:

- Standard and heavy-duty

- Self-locking versions for added security

- Inch and metric sizes

- Solid and thinwall designs

These are ideal when repeat fastening or high torque loads are involved. Applications include aerospace assemblies, military-grade equipment, marine hardware, and industrial machinery.

Preventing Downtime with Thread Repair Inserts

Thread failure can stop an entire assembly process. Acme’s thread repair inserts let you restore stripped threads without replacing the entire part—a major time and cost saver.

Key benefits of Acme thread repair solutions include:

- Permanent thread restoration

- Simple, quick installation with common tools

- Stronger-than-original thread performance

- Resistance to corrosion, vibration, and fatigue

Whether you're servicing field equipment or maintaining a production line, Acme inserts deliver consistent performance and get you back online faster.

Acme Drill Bushings: Precision Where It Counts

In repetitive drilling operations, accuracy is everything. Acme drill bushings provide precise tool guidance, reduce tool wear, and ensure repeatable results. These bushings are essential in:

- Drill jigs and fixtures

- Aerospace and automotive production

- Precision machining operations

Acme offers both press-fit and renewable bushings, all made to ANSI and military standards. With these in place, you can be confident every hole will meet spec—every time.

Trusted Across Critical Industries

Acme products are designed for environments where thread integrity is mission-critical. Key industries include:

- Aerospace – to secure fasteners in thin-walled and high-vibration structures.

- Defense – for field-repairable systems requiring rugged thread performance.

- Automotive – to restore stripped threads in castings and reduce waste.

- Medical equipment – where drilling accuracy and reliability are paramount.

- Energy & rail – to maintain infrastructure with minimal downtime.

In all of these industries, the cost of failure is high. Acme’s inserts and bushings help reduce that risk—and HTF ensures you get the right product when you need it.

Why Choose HTF for Acme Solutions?

Selecting the right insert or bushing isn't just a matter of thread size. Factors like parent material, tensile strength, load direction, and installation environment must all be considered. That’s where HTF adds real value.

We support our customers with:

- Expert technical guidance

- Application-specific recommendations

- Free product samples to validate fit and function

- Same-day shipping on stocked Acme products

Whether you're designing a new assembly or repairing a critical part, we make sure you get what works—quickly and confidently.

Keep Critical Inserts Stocked with InventoryXpert

When thread repair components are out of stock, downtime stretches and costs rise. HTF solves this with InventoryXpert, our barcode-based inventory management system.

InventoryXpert lets you:

- Set custom minimums for Acme inserts

- Scan barcodes to reorder instantly

- Track inventory in real time

- Use existing part numbers and bin locations

- Add optional secondary approval before ordering

This self-managed tool helps teams keep essential inserts, bushings, and repair parts available—without overordering. It’s ideal for MRO teams, procurement managers, and assembly lines where uptime matters.

Avoid the Hidden Costs of Thread Failure

Stripped threads often seem like a small issue—but the downstream costs can be enormous. Lost production, emergency part orders, and rework all eat into budgets. Acme keylocking inserts and drill bushings provide a simple, rugged solution to this common problem.

And with HTF’s support, you can:

- Prevent failures before they happen

- Restore damaged components without full replacements

- Ensure every insert fits your specs and schedule

- Stay stocked and ready with InventoryXpert

Work Smarter with HTF and Acme

At Hi-Tech Fasteners, we don’t just supply fasteners and inserts—we help you solve problems. Whether you're designing a high-tolerance aerospace part or keeping a rail system in motion, our team is here to make sure every insert works, every time. Request a quote today.

.png?width=800&name=InventoryXpert-Blog-Alt%20(5).png)